Industrial Process News is proud to feature British Encoder Products Company (BEPC) for our Products of the Month profile.

BEPC is the European branch of the Encoder Products Group, which is a worldwide manufacturer of motion sensing and control devices. As a customer driven company, BEPC is highly responsive in the areas of customer service and technical support, with an acute focus on high performance, excellent delivery and competitive pricing. These values work together to ensure BEPC provides products and services of the highest quality to guarantee great value for money for every customer. Indeed, BEPC prides itself on building long-lasting relationships, a principle which has facilitated the company’s impressive growth since its inception.

BEPC is the European branch of the Encoder Products Group, which is a worldwide manufacturer of motion sensing and control devices. As a customer driven company, BEPC is highly responsive in the areas of customer service and technical support, with an acute focus on high performance, excellent delivery and competitive pricing. These values work together to ensure BEPC provides products and services of the highest quality to guarantee great value for money for every customer. Indeed, BEPC prides itself on building long-lasting relationships, a principle which has facilitated the company’s impressive growth since its inception.

Established in 1969 by Bill Watt, the Encoder Products Group is celebrating its 50th anniversary this year. In the sixties, Bill invented an encoder to provide an output to feed directly into the growing number of counters and PLCs which were being used at the time. His invention, the ‘cube encoder’, revolutionised the encoder world and is now an industry standard.

Established in 1969 by Bill Watt, the Encoder Products Group is celebrating its 50th anniversary this year. In the sixties, Bill invented an encoder to provide an output to feed directly into the growing number of counters and PLCs which were being used at the time. His invention, the ‘cube encoder’, revolutionised the encoder world and is now an industry standard.

Recently, BEPC released its new range of absolute encoders, which provide a unique code for each increment of shaft rotation. This means that the encoder indicates both that the shaft position has changed, and the absolute position of the shaft. The company now offers a higher resolution of 16 bits for single turn resolution and 43 bits for multi-turn resolution, meaning the encoders can measure with greater resolution and have a longer run-time before reset.

We had the pleasure of speaking to Stephen Evans, General Manager, who told us more about the advantages of BEPC’s absolute encoders. “This range is ideal for systems which need exact position information in order to prevent damage to machinery and its operators. This is particularly valuable during power loss, when the absolute encoder will maintain its value without being powered, so any movement during the loss of power is tracked and retained for immediate transmission once power is restored.”

We had the pleasure of speaking to Stephen Evans, General Manager, who told us more about the advantages of BEPC’s absolute encoders. “This range is ideal for systems which need exact position information in order to prevent damage to machinery and its operators. This is particularly valuable during power loss, when the absolute encoder will maintain its value without being powered, so any movement during the loss of power is tracked and retained for immediate transmission once power is restored.”

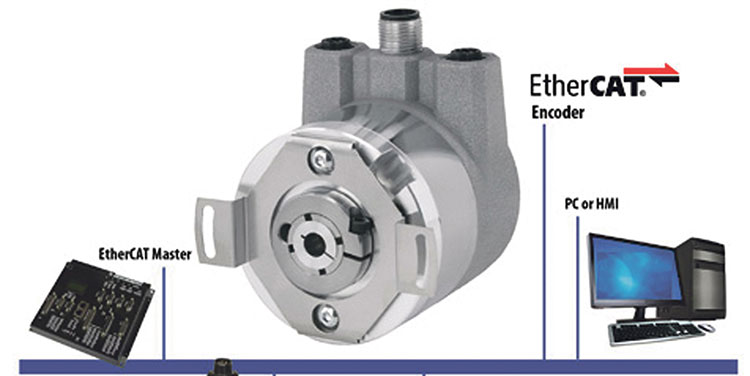

The absolute range has been offered with SSI and CANopen protocols for years, and BEPC has recently added encoders with EtherCAT capabilities, with more protocols to follow as the range is developed and expanded. BEPC’s A58HE (hollow bore) and A58SE (shaft) models are EtherCAT ready and designed for harsh factory and plant environments. Suitable for a variety of applications, these encoders plug directly into a network with minimal prerequisites, working in various configurations with the ability to continue communication in the event of a line break. Furthermore, these models work with CANopen over EtherCAT, so implementation remains straightforward for those who are familiar with CANopen.

One of BEPC’s strongest ranges is their programmable incremental encoders, which have been specifically designed for the challenges of an industrial environment. Within this robust casing is a selection of advanced electronics which allow the encoders to be programmed to precise application needs. The optional programming module means users can select from six different output types, choose from 32 different waveforms, and program any resolution from 1 to 65,536 PPR. This means that a single encoder can be configured for multiple applications, making it possible to replace numerous different part numbers with one encoder, thus saving inventory and down time replacement costs. What’s more, these programmable incremental encoders can be shipped with specifications pre-programmed, meaning there is no need for onsite programming.

One of BEPC’s strongest ranges is their programmable incremental encoders, which have been specifically designed for the challenges of an industrial environment. Within this robust casing is a selection of advanced electronics which allow the encoders to be programmed to precise application needs. The optional programming module means users can select from six different output types, choose from 32 different waveforms, and program any resolution from 1 to 65,536 PPR. This means that a single encoder can be configured for multiple applications, making it possible to replace numerous different part numbers with one encoder, thus saving inventory and down time replacement costs. What’s more, these programmable incremental encoders can be shipped with specifications pre-programmed, meaning there is no need for onsite programming.

It is evident that BEPC has remained up to date with the changing needs of the market place since its innovative beginnings. Their absolute encoder range has been expanded in the last year, with further additions to follow in the near future. To ensure its finger is on the pulse of the industry’s evolving requirements, BEPC’s essential engineering division, based in the US, looks at the market and produces what it demands, working hard to develop products which solve real problems that are surfacing within automation. “We are leading the way, maintaining our position at the forefront of new developments in the encoder world,” said Stephen. Indeed, with further innovations on the horizon, BEPC will be attending the Engineering Design Show at the Ricoh Arena, Coventry on 16–17 October 2019 where the company is hoping to showcase its new range of products.

It is evident that BEPC has remained up to date with the changing needs of the market place since its innovative beginnings. Their absolute encoder range has been expanded in the last year, with further additions to follow in the near future. To ensure its finger is on the pulse of the industry’s evolving requirements, BEPC’s essential engineering division, based in the US, looks at the market and produces what it demands, working hard to develop products which solve real problems that are surfacing within automation. “We are leading the way, maintaining our position at the forefront of new developments in the encoder world,” said Stephen. Indeed, with further innovations on the horizon, BEPC will be attending the Engineering Design Show at the Ricoh Arena, Coventry on 16–17 October 2019 where the company is hoping to showcase its new range of products.

“We are doing extremely well,” expanded Stephen. “We are growing exponentially, with further growth in the pipeline as we move forward. We are maintaining and growing our market share worldwide, and it’s fair to say we possess a significant share of the encoder market in the UK. Things are definitely moving in the right direction for us, and I would just like to take this opportunity to say a huge thank you to our customers and suppliers, without whom we would never have had the success we have achieved over the last 50 years.”

Indeed, BEPC is cementing its status as an industry leader, offering unparalleled expertise in the development of ground-breaking encoders for all sectors of automation, ensuring they are staying ahead of the game to address the industry’s constant progression. If you would like to find out more information on BEPC’s full range of products and services, head to their website or get in touch using the contact details below.

T 01978 262100

sales@encoder.co.uk

www.encoder.co.uk

www.encoder.com