In this issue of Industrial Process News, we are honoured to select Thermal Vision Research for our End of Year Recommendation.

Thermal Vision Research (TVR) is the UK premier distributor for Teledyne FLIR’S IR thermography camera range, designed for specialist R&D applications. Established in 2017 by Director Matthew Clavey, TVR is based at Aztec West Business Park near Bristol, in South Gloucestershire.

Thermal Vision Research (TVR) is the UK premier distributor for Teledyne FLIR’S IR thermography camera range, designed for specialist R&D applications. Established in 2017 by Director Matthew Clavey, TVR is based at Aztec West Business Park near Bristol, in South Gloucestershire.

The last time we featured TVR: Matthew, together with Teledyne FLIR Business Development Managers was about to feature at the Engineering Design Show (EDS): held at the Coventry Building Society Arena from 12th-13th October.

The team showcased a state-of-the-art thermal lab, with a wide range of products including:

- The RS Platform: Capable of seeing images in kilometres – perfect for military and defence operations

- Microscope cameras: With images of two microns per pixel.

- Premiere Uncooled A700 camera: 640×480 (60 Hertz) – with research studio – great sensitivity and perfect for university research and entry-level industrial applications.

- The ‘King of Cameras’: The cooled HD 1280×1024 sensor, able to run at 180 Hertz, to 3kHz. Produces fine detail, down to 0.02 degrees.

The EDS show was a resounding hit, with stand fever pitch around the thermal selfies! Visitors were astounded by the high resolution and magnification capabilities of the Teledyne FLIR camera range.

The EDS show was a resounding hit, with stand fever pitch around the thermal selfies! Visitors were astounded by the high resolution and magnification capabilities of the Teledyne FLIR camera range.

We caught up with Matthew post-EDS show to find out how things have progressed, “We are excited to be showcasing the all-new FLIR’s 80-degree wide angled lens. It has full compatibility with A400/500/700 science range and is available now from our website.”

“That’s not all! We ran our first FLIR RS6780 advanced sensor showing during November. The RS6780 has a three-position motorised filter wheel, with premium quality thermal images across long-range and tracking. It is optimally-designed for researchers as a radiometric camera system, due to the calibration for temperature and radiance measurements. Our demonstration showed the optional extender lens up to 750mm, allowing tracking up to 30km away in the distance: perfect for defence operations, wind turbine monitoring, rocket launch monitoring through to wildlife research around the world!”

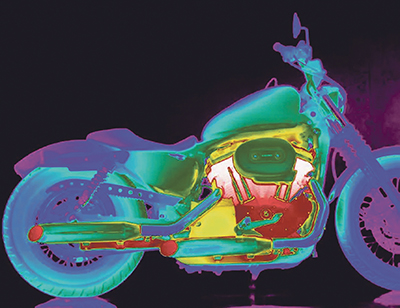

The R&D capabilities of FLIR thermal cameras are limitless, offering razor-sharp images and measurements, perfect for many applications from defence, military, renewable energy monitoring, battery testing, research, through to cutting-edge wildlife conservation monitoring.

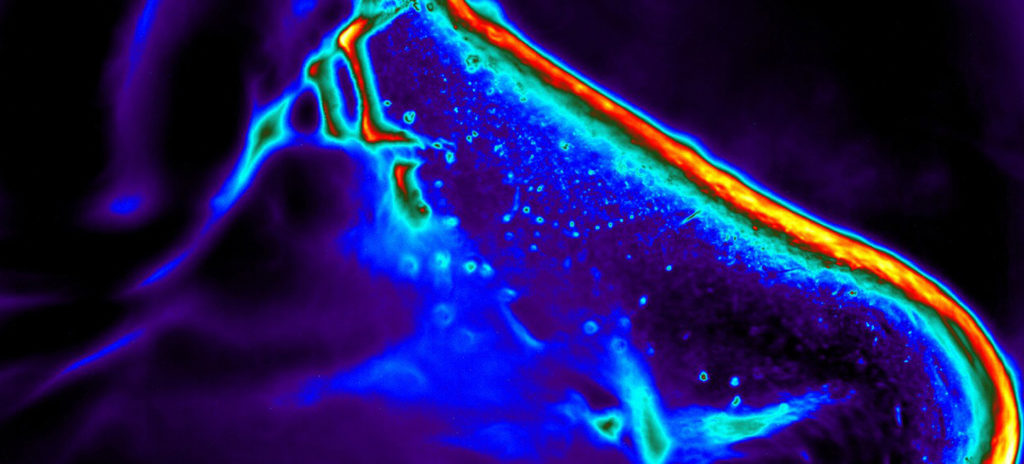

We featured Thermal Vision Research previously for its outstanding research collaboration with The Aircraft Research Association (ARA): a dedicated UK aerodynamic research institute. The mission was to test the hybrid laminar flow control hypothesis. TVR loaned its Teledyne FLIR T1K to locate accurate temperature changes in the high-speed transonic wind tunnel, with speeds up to Mach 1.4 (1,000mph.) As a result of the air turbulence generated from the high speeds, the precise point of transition for airflow changes by less than 1.

We featured Thermal Vision Research previously for its outstanding research collaboration with The Aircraft Research Association (ARA): a dedicated UK aerodynamic research institute. The mission was to test the hybrid laminar flow control hypothesis. TVR loaned its Teledyne FLIR T1K to locate accurate temperature changes in the high-speed transonic wind tunnel, with speeds up to Mach 1.4 (1,000mph.) As a result of the air turbulence generated from the high speeds, the precise point of transition for airflow changes by less than 1.

The Teledyne FLIR T1K provides an accurate visualisation of the airflow in-situ, without adversely affecting the aerodynamic variable. These meticulous point of transition results allowed the Aircraft Research Association (ARA) to prove the hybrid laminar flow control hypothesis, within controlled test conditions.

The Teledyne FLIR T1K provides an accurate visualisation of the airflow in-situ, without adversely affecting the aerodynamic variable. These meticulous point of transition results allowed the Aircraft Research Association (ARA) to prove the hybrid laminar flow control hypothesis, within controlled test conditions.

The ARA are now at the incredible, early stages of marketing the pioneering FLIR T1K wind tunnel concept design to engineering companies, as a blueprint towards long-haul sustainable flights.

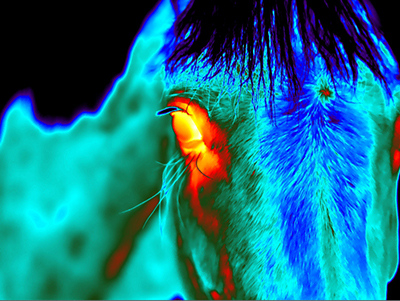

A second colloboration we reported on was with Northern Rail, through the ingenious trialling of an ‘intelligence train,’ installed with a FLIR A6750sc cooled thermal camera. The camera works with acoustic monitors, G-shock Bogie, AI camera, radar dome, LIDAR horizon-scanning cameras and precision-driven 180° thermal imaging software, providing precision-driven accuracy on railway track infrastructure problems. The camera captures clear, sharp images in transit, even at high-speeds: the pixels generated in sub-one milliseconds of track sections and full-frames of 125Hz. The cooled camera tracks up to 100 metres ahead on the tracks and automatically uploads detailed track date to a SMART-cloud platform, which can then be accessed by Northern Rail remotely.

Matthew explained the advantages of using the FLIR A6750sc in this manner, “It allows the train company to keep the track open for regular train services, saving costly downtime and thermal imagining target precise areas for track maintenance, earmarking for strategic future engineering maintenance.”

Matthew explained the advantages of using the FLIR A6750sc in this manner, “It allows the train company to keep the track open for regular train services, saving costly downtime and thermal imagining target precise areas for track maintenance, earmarking for strategic future engineering maintenance.”

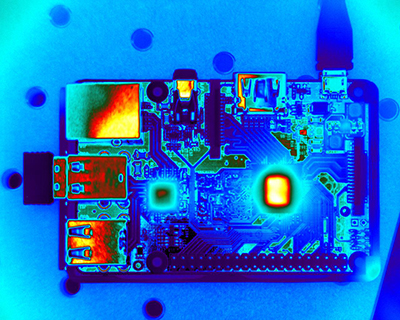

With the recent surge towards battery-electric cars across the UK, especially with the planned 2035 petrol and diesel ban, many businesses and households are considering the shift towards electric vehicles. One ongoing concern though is the safety around EV Batteries, with some high-profile media attention on cargo ship fires recently.

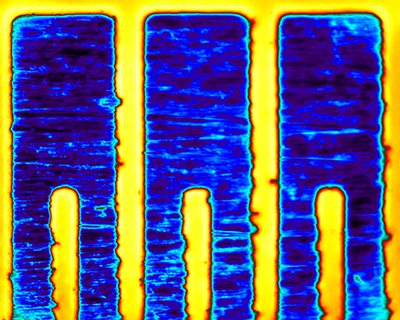

The Teledyne FLIR high-speed thermal camera offers accurate EV test safety reassurance, with more accurate high-speed imaging results than previous thermocouples and general IR devices, pinpointing the exact location of short-circuits and heat spreading.

The high-speed camera gives slow, thermal imaging captures at high temperatures of over 3,000°C and provide details of the thermal management system, during the EV battery testing period.

TVR are happy visit businesses on-site, to demonstrate camera range capabilities and offer camera hiring, lease and purchasing options.

For more information on TVR, please see the website below:

T 0333 200 4667

info@thermalvisionresearch.co.uk

www.thermalvisionresearch.co.uk

https://www.linkedin.com/in/matthew-clavey-b8ab082a