5 advantages of custom-made cases for equipment

5 advantages of custom-made cases for equipmentCustom-made equipment cases boast several advantages over standard cases thanks to the high-quality materials and customisable parts. Bespoke cases work flexibly around your essential equipment.

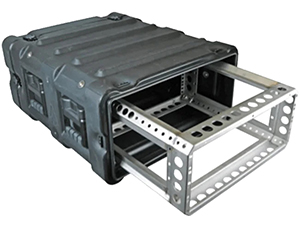

Any shape, size or quantity is catered for with custom-made cases. This means that your equipment will be guaranteed to be protected against all potential hazards. Whether you require a reinforced rugged case for rough handling or a cooling system to protect electronic equipment from overheating, custom cases listen to your specific needs and exacting requirements. You know your equipment and what it needs to be protected against, and a custom case can provide the perfect all-in-one solution.

The main purpose of a case is to protect your expensive equipment, being able t o ensure the full protection of valuable items offers the ultimate peace of mind. You need to be confident in relying on your equipment and a custom case ensures exactly that. Custom cases are made from robust materials such as polyethylene polymer to withstand impacts and the custom foam ensures a snug and secure fit.

o ensure the full protection of valuable items offers the ultimate peace of mind. You need to be confident in relying on your equipment and a custom case ensures exactly that. Custom cases are made from robust materials such as polyethylene polymer to withstand impacts and the custom foam ensures a snug and secure fit.

Lightweight polyethylene polymer makes lifting and transporting equipment much easier. Custom handles can ensure that cases can be safely transported without rough handling or accidental damage. Companies that regularly transport equipment can add wheels to cases to minimise the physical effort of moving heavy items. Additional fittings such as pressure valves can be another great option when transporting valuable equipment. The key to a great custom case is the expert behind it, who can offer advice on what works best for your equipment.

Saves on air freight costs

Saves on air freight costsIf you regularly ship equipment by air, custom cases can save a great deal of money. The extremely lightweight materials will significantly reduce airfreight costs. On top of this, valuable equipment can get damaged when transported by air. Thankfully, custom cases use extremely durable materials to ensure that your equipment can withstand rough handling.

At CP Cases, our custom cases make protecting your equipment its priority. Using high-quality polyethylene polymer, custom cases are ruggedised, reliable and strong. The rotomoulding process ensures that edges and corners are reinforced, protecting equipment from any accidental damage. Custom foam inserts cushion equipment, absorbing any impact and preventing items from moving out of place during transportation. The main reason for commissioning a custom case is to keep your equipment safe, which is exactly why strength and durability are so important.

Custom-made case product options

Custom-made case product optionsNow that you know the countless advantages of custom cases, it’s worth understanding the different ways in which cases can be customised for your specific equipment needs. With so many product options available, it can be overwhelming, which is why at CP Cases we offer expert advice for each unique case.

Making your equipment instantly recognisable in a busy warehouse or airport can save a lot of time and hassle. What’s more, our printing, labelling and branding can also help enforce a positive image of your company, boosting your recognition with clients and at events. Your unique branding represents your business and what better place for it than on the equipment cases you use on a daily basis? From silkscreen printing to engraved labels and sewn-on badges – custom cases are truly an extension of your organisation.

Partitions and dividers

The purpose of a custom case is to fully support the use of your equipment and meet specific access needs. As a result, custom partitions and dividers can help you organise equipment and separate items to make your job easier. Using CAD tools, precise drawings can be translated into high-quality partitions and dividers that specifically work for your equipment, shielding valuable or volatile items from one another. Make the most out of your custom case by including partitions to ensure your equipment is safe and protected.

EMI stands for electromagnetic interference, which refers to the effect that a magnetic field can have on other devices nearby. When electricity flows into a conductor, this generates a magnetic field, which can easily interfere with data signals. So, EMI shielding protects against this, ensuring that your equipment runs smoothly. If you have valuable specialist equipment that you need to rely on, you can fit your custom case with EMI shielding in which a metallic shield is placed around your equipment, absorbing any incoming signals. Not only should a case protect your equipment but enhance its performance.

External finishing

External finishingExternal finishing options on custom cases are designed to meet your exact requirements in both appearance and functionality. For example, aluminium cases can be produced in plain or rigidised aluminium with surface finishes from powder coating to anti-reflective finishes. These options can both work to boost durability whilst adhering to your brand aesthetic. The finishing touches to your custom case can add an extra layer of protection and practicality whilst giving a unique identity to your equipment.

In order for custom cases to be truly fit for purpose, they need to be customisable right down to the construction itself. Being able to access and transport your equipment in the most practical way possible is paramount at CP Cases. From adding wheels to make moving heavy equipment easier to pressure relief valves that ensure maximum protection, you can add additional fittings and options to optimise how you use and transport your equipment. Sophisticated locks can be added to boost security and handles to ensure safety when picking up heavy equipment.

A custom protective case is the ultimate bespoke solution to transporting your valuable equipment, keeping it safe and maximising its performance. We rely on our equipment in multiple high-pressure situations, so having a customisable case that works for your exacting requirements is the ideal companion.